development history

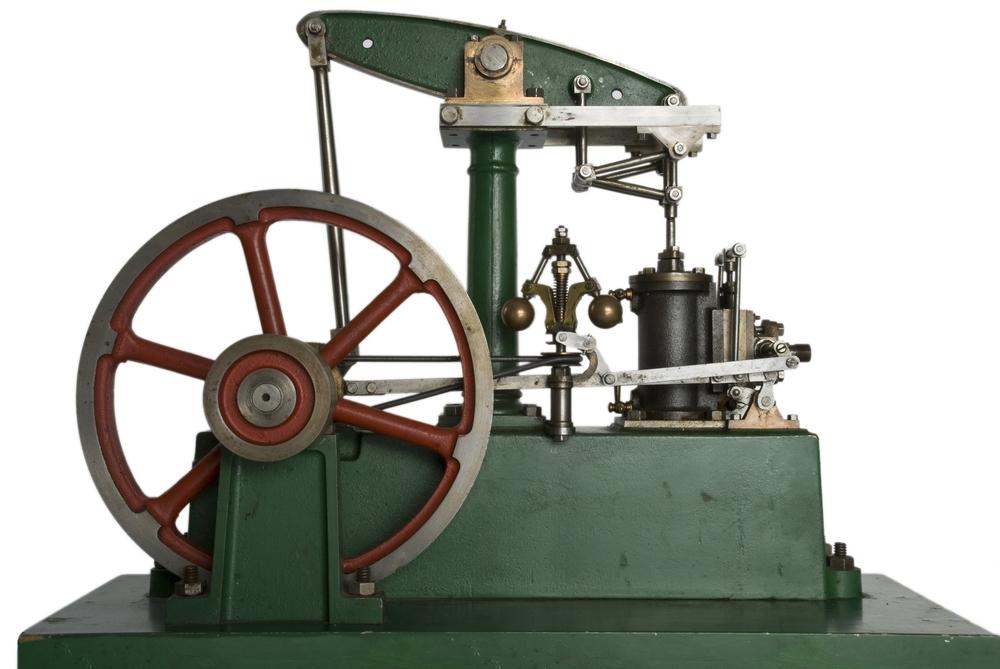

1958 was built in the Hudong Shipyard of "democracy No. 14" B coastal cargo and passenger ships using the three four-cylinder reciprocating steam engine expansion of 1100kW. June 1958 made of Hudong Shipyard 1765kW five-cylinder single-flow steam engine for the "Mir 25" and "No Peace 28" coastal cargo ship. Since the entire reciprocating steam power plant efficiency is low, poor balance of properties, size and other reasons when the weight has been basically eliminated in foreign countries.

20 drawings from the 1960s to introduce the Soviet Union, built by Dalian Shipyard of 9555kW (13000hp) steam turbine used ten thousand tons ocean-going cargo ship hosts "leap forward" and "red flag" number. By the 1970s, according to the Shanghai Turbine Works "leap forward" was the introduction of the steam turbine drawings, improvements to power 1 1800kW (16000hp) steam turbine for the "Yuanwang" space tracking ship, the ship was mainly on account of many measuring instruments and equipment high vibration and noise requirements. The main parameters of the ship power plant steam pressure of 5MPa, superheated steam 470 ℃, host rated power 11 800kW, 5 turbogenerator units 5 × 1200kW. Primary and secondary turbine the group consisting of 2 sets of 32t / h of the D-type water tube boiler in parallel for the steam cabin of central control, the host starts, the parking, reversing, shift, and the main boiler and other auxiliary equipment are monitoring the host control room, and through the micro monitoring processor for all alarm thermal parameters, color display, automatic printing. Ships

propulsion steam turbine power plant in the world between 1970 and 1976 to build about 120 per year, 1977 Year - 1980 to build about 20 only a year after 1986 in addition to ships and nuclear power large aircraft carriers, outside the ship has been rarely used. But in the 80 years after our large ships are still used.

around the mid-20th century, the major naval country in the world uses a lot of steam power plant as a main power large ships, the level of the main steam power plant boiler capacity 65 ~ 120t / h, every main steam turbine power station 27500kW (35000 hp), 36800kW (50000 hp) and 51500kW (70000hp), using the parameters of steam 4.4 ~ 6.3MPa, 450 ℃ -490 degrees Celsius, 8.27 MPa U.S. carrier is used, 510 ℃, fuel consumption at full speed is 381 ~ 558 g / (kW · h) of a multi-type uniaxial propulsion steam power plant ~ 26500kW (36000hp) power 1 1756kW (16000hp).

Features

steam power plant due to the steam turbine operates on a continuous process of high parameters working medium and high rotation speeds of the rotor, so that the unit power is large; stable operation In operation, low noise, low vibration , good reliability, long life, life of up to more than 105 hours; use of poor quality fuel oil. However, due to the large mass of power units ship steam power plant, large size, complex pipeline system; large fuel consumption and low efficiency of the device; the same fuel reserves, low endurance; poor mobility, the warm-up time required long, long time transition conditions for marine propulsion is its Achilles heel, thus limiting the development of ship steam power plant from the development point of view.

composition

in a steam power plant as an example a ship.

Ship with steam boilers are generally the main power plant, high (medium), the low pressure turbine, turbine reversing, the main condenser, shunting means, a reduction gear box shaft, each independent turbine type auxiliary, and deaerator feed water preheater, the control and monitoring system components.

(1) Ship with a main boiler

during operation of fuel and air by mixing the post-combustion releases heat, the steam drum water absorbs heat generated saturated steam in the furnace, steam concentrate in the vapor portion, the majority of the saturated steam superheater steam leaders, after after reheated steam becomes superheated, and are sent to the equipment required to be used. The basic performance of the boiler as follows.

① refers generally to steam pressure in the steam pressure in the boiler, modern marine boiler steam pressure at 4.41-8.33 MPa.

② superheated steam temperature refers to the temperature at the outlet of the steam superheater, boiler modern ship superheated steam at a temperature of 400 ~ 510 ℃.

③ boiler efficiency generally refers to the ratio of the total heat of the boiler is effectively accepted amount of heat per unit time for complete combustion of the fuel in the boiler furnace can be released within the same time. Modern ship in 0.7-0.9 boiler efficiency.

(2) ship steam turbine means

turbine device consists of a high pressure turbine;, the low-pressure turbine; reversing or reverse stage turbine; main condenser; a reduction gear box; shunting means and other components. First be converted to thermal energy in the steam turbine plant of the nozzle into kinetic energy, and then change in the moving blade steam kinetic energy into mechanical work machine.

is the effective power turbine group takes into account both internal loss of the turbine, and the turbine considering various external losses (also known as mechanical loss, the loss of entraining idle reversing gear overcome various bearings loss resistance, loss gear reducer shaft losses after) the actual transmitted power propulsion shaft. Effective efficiency

is the ratio of the steam turbine plant and theoretical effective power of the power turbine steam turbine plant.

ship is at sea, turbine propeller and a host of work must match in order to give full play to their respective performance. A match well, the ship may also be maintained better mobility possible under special conditions (e.g. towing, oars navigation, etc.).

Auxiliary Main Turbine (3) a steam turbine plant

using various auxiliary steam turbine to drive the turbine is called auxiliary. Since less total secondary turbine stages, usually a single-casing.

accordance with the layout of the cylinder centerline, the steam turbine can be divided into ship both horizontal and vertical. The former is the level of the centerline of the cylinder, which is perpendicular to the cylinder centerline. The main turbine and turbine are used horizontal. Due to the small vertical turbine in the cabin area, it used to drive a variety of special auxiliary equipment (water pump, engine oil, fuel pumps, circulating pumps, etc.).

Ship auxiliary exhaust pressure condensing steam turbine and a back pressure has two. Condenser exhaust into the former, so the exhaust pressure is equal to the condenser pressure (vacuum); the latter is collected in the exhaust gas exhaust manifold, the exhaust manifold pressure is greater than atmospheric pressure, referred to as back pressure, the feed water for steam heater, water boiler water making equipment.

mounting arrangement

mounting arrangement of the steam power plant to the Russian "modern" class (SOVERMENNY) representative universal destroyer, main boiler, a steam turbine and the gear box is usually provided with a watertight compartment, form a complete set of steam power plant. Typically the left and the starboard side are attached to the main boiler arrangement, a steam turbine and a gearbox. In principle, the devices are arranged in the nacelle to be easy to install, commissioning, operation, maintenance and damage control, and so as to form an annular passage within the cabin, so as to arrive crew combat position in an emergency state.

more steam power plant system, multi-line and high-temperature steam, especially the larger diameter cladding insulating material, so installation and piping arrangement to fully consider any surrounding a hull member, the spacing between the cables, auxiliary equipment, is generally greater than the distance of 50 mm left; equipment parts and special tools fixedly secured at a position near the spare room or premises maintenance activities, higher surface temperatures of the equipment and piping to be flammable piping, tanks, bins maintain an appropriate distance, electrical and electronic equipment, and above the equipment cabinet linker should avoid oil, water, gas, steam drains of piping; with pressure relief devices and water, the steam pipe safety valves, relief valves be led to the discharge opening at the outboard or safety.

each system disposed within the cabin for the maintenance of the main auxiliary equipment, leaving the space necessary for the replacement, as the detached small tubes, cables, ventilation ducts and other embodiments where the installed equipment.