Classification

By its role is divided into two categories:

1. Flock, medium or hollow The requirements are not high, about 30% to 100%, mainly pursuing the light and warm, in order to improve its rebound rate, it can also be made into a diaphragm, heat treatment to form three-dimensional curl;

2. Separation membrane, medium hollow degree, and cross-sectional circle rendering requirements, membrane wall micropores and distributions have certain requirements, and can also apply a layer or two layers of different ultra-thin separation layers to improve separation effects and Selective.

Preparation

1. Using annular hollow, C-shaped or eccentric hollow spinneling plate through melt spun (polyester, etc.) or solution wallage; / p>

2. with medium air type (individual C-shaped) spinneret, through dry wet spun or melt spinning, some central portions need to pass air or different Solden liquid, make a series of products.

Characteristics

lighter heating

High school empty structure reduces the weight of the fiber 20%, and can contain a lot of still air to make it fabric in lightweight At the same time, warm performance is increased by 65% compared to ordinary homogeneous fabrics;

Plenty of soft

products Become a more painful comfort;

Dry and moisture

compare daily thick warm fabrics, it is easier to moisture and comfortable.

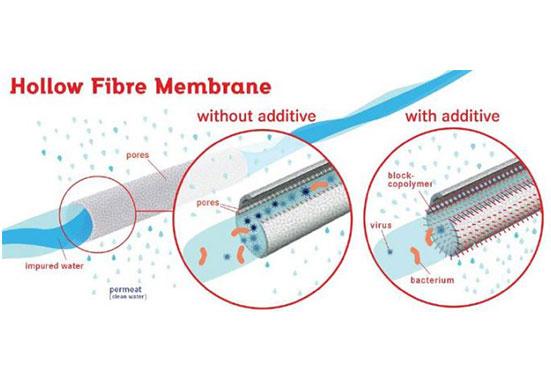

Ultrafiltration membrane

The characteristics of the hollow fiber ultrafiltration membrane assembly are as follows:

1) housing adopts anti-impact ABS, with pressure capacity at 16kg The above, and the wall thickness is 1 mm, which can be affected by the various pressure impacts that may occur in the water water, ensuring that the rupture phenomenon will not occur under impact water pressure, avoiding the ultrafiltration membrane in the process of long-term pressure, material production Creep causing leakage.

2) Each HUF90 membrane is filled with 1400 membranes, and the length is less than 100 mm, an increase of 15% membrane area, and the effective film area is higher than the same specification of the country in China. Improved water content.

3) The end cap is a hemispherical projection, which makes the inlet water more uniform compared to the conventional end surface structure, and the wall thickness is 1 mm to ensure water pressure in the impact Do not rupture.

4) Bonding between the housing and the threaded sleeve is selected from French imported glue bonding, the bond length is extended, and the connection gap is uniform. Will no leakage during use. Deaches, and fully achieves a health standard.

5) The end cap and the housing connection thread use a sawtooth thread, increasing the torque and load, and there is no slip. Water leakage.

6) The effective area of the membrane is large, the water flux is large, and the pure water flux is 1800 liters, which is much higher than the domestic same specification.

7) Design of pressure and leak-proof structure, ensuring that the HUF90 hollow fiber ultrafiltration membrane does not have leakage, degeneration, slip, glue, etc..

8) The water port is a live jacket of a 45mm thread of the national standard, which can be bonded directly to 1 inch ABS or PVC drinking pipe without an additional installation of the live joint. When replacing the HUF90 hollow fiber ultrafiltration membrane assembly, simply remove the four standard diameters of the inlet and outlet, remove the entire hollow fiber ultrafiltration, and then replace the new HUF90 hollow fiber ultrafiltration membrane Component can be.

Due to the function of the hollow fiber ultrafiltration membrane is to remove the impurities contained in the stock solution, excellent in hollow fiber ultrafiltration membranes with low molecular weight, and the impurity contamination can be faster, the film surface will be The various hazardous impurities that are trapped, even the film holes are clogged by more subtle impurities and reduce their separation performance. The method of cleaning film can be divided into two categories: physical methods and chemical methods.

Maintenance method

Physical Cleaning method

Shihan ultrafiltration membrane consumables utilize mechanical strength to remove membrane surface pollutants. Any chemical reaction occurs throughout the cleaning process.

1, isometric hydraulic rinse method: First turn off the ultrafiltration exit valve, fully enhance the water outlet valve, at which time the pressure in the inner and outer side of the hollow fibers gradually tends to equal, due to the pressure difference adhesion to the film The surface of the surface is loose, and the flow rinsing surface is increased, which is effective on the surface of the removal film;

2, water gas mix cleaning method: Purifying compressed air and water flow into super In the filter, the water gas mixture will remove more solid impurities in the surface of the membrane. The effect is better, but should pay attention to the pressure and flow of compressed air;

3, hot water and pure water rinse method: hot water (30 ° C ~ 40 ° C) flush film surface, for those sticky The impurity removal effect of thermal solubility is obvious. Pure water is soluble. The pure water circulation is more better;

4, a negative pressure reverse rinsing method: is a rinsing method from the negative surface of the film, a hollow fiber or capillary ultrafiltration membrane having a dense layer inside and outside It is more appropriate.

Chemical cleaning method

Using some chemicals to chemically or dissolve the hazardous substances to achieve the purpose of cleaning.

1, acid washing: Commonly used acid has hydrochloric acid, oxalic acid, citric acid, etc. The pH of the solution after formulation is determined by the type. For example, Ca film cleaning liquid pH = 3 to 4, other PS, SPS, PAN, PVDF and other films pH = 1 to 2. The water pump is used to circulate or soak 0.5 to 1 h, and the effect of the inorganic impurity is good;

2, alkali washing: Commonly used base is mainly sodium hydroxide, potassium hydroxide and sodium carbonate. The pH of the formulated alkali solution is also determined by the type of film, except that the Ca film is required to be about 8, and other corrosion resistant pH = 12, the water pump is used to circulate or soak 0.5 ~ 1 h, and the organic impurities and oil are effective;

3, an oxidative cleaning agent: Ultrafiltration membrane is cleaned by aqueous solution of 1 to 3% h 2 o 2 , 500 ~ 1000mg / L NaClo. It has been removed from dirt and kills the bacteria. H 2 o 2 and NaClO are commonly used fungicides.

4, addition of detergent cleaning: Equate washing such as 0.5% ~ 1.5% gastric protease, trypsin. The removal of protein, polysaccharide, and oil pollution substances are effective.